Plasma Coating

There are three common states in nature: solid, liquid and gas. When enough energy is continuously applied to the gas state, the outer electrons get rid of the binding of the nucleus and become free electrons. The nucleus (positively charged ion) and the electron (negatively charged) separate and move freely. This mixed state, dominated by a large number of freely charged particles (ions and electrons), is generally nearly electrically neutral.

In the laboratory, the form of producing plasma is mostly gas discharge. According to the different plasma excitation sources, it can be divided into DC plasma, low frequency plasma, medium frequency plasma, radio frequency plasma and microwave plasma. Combustion method, shock wave method and laser irradiation method are also one of the methods used to obtain plasma in the laboratory. Plasma technology has been applied in many fields, especially in the surface modification of materials with a lot of research and potential.

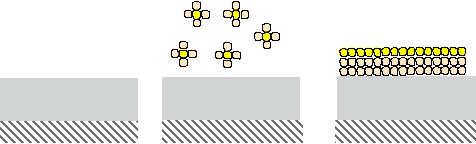

PLASMA produces reactive particles and free radicals through ionization gas. Through physical and chemical reactions such as oxidation, reduction, cleavage, cross-linking, and polymerization, the surface of materials is peeling off and decompose contaminants, changing the surface properties of materials, so as to optimize the surface properties and realize the purpose of cleaning, modification, etching, and coating.