When plasma acts on a solid surface, it produces multiple effects:

Chemical reaction: Free radicals react with organic matter on the surface, decomposing it into gaseous products (such as CO₂ and H₂O), achieving cleaning.

Plasma technology offers different solutions for many types of molecular-level contamination, depending on the subsequent treatment. You can choose from a variety of plasma processes to meet your specific application needs.

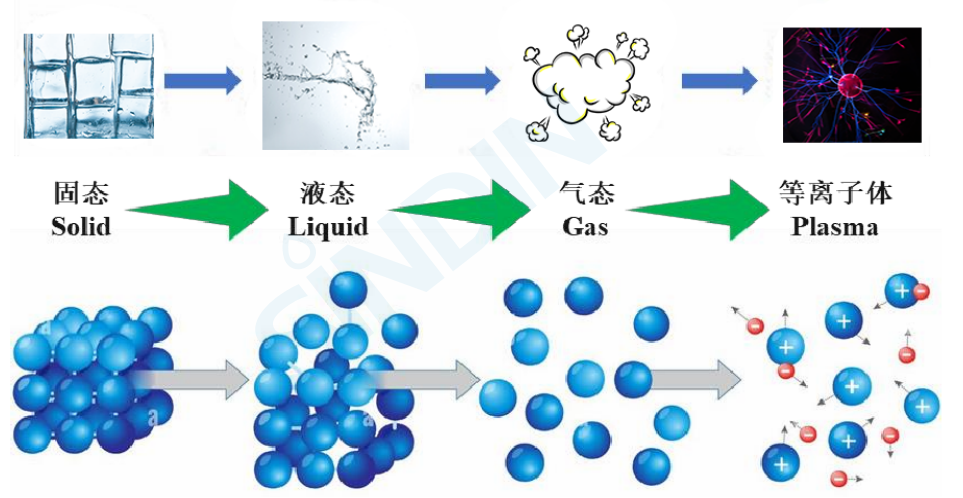

Plasma cleaning:Plasma cleaning utilizes low-temperature plasma to physically or chemically modify the material surface.

• Environmentally friendly and pollution-free

• Efficient surface activation

• 3D surface treatment, suitable for complex geometries

• Wide material compatibility

• No damage to the substrate

• Inline integration

• Quick effect

• Controllable