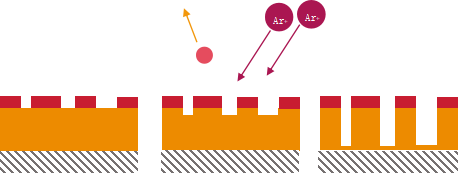

Plasma etching is a process where active particles in the plasma react chemically or physically with atoms on the surface of a material, producing volatile products and thereby removing material. It is generally categorized into:

Physical sputtering

①.Principle: High-energy ions (such as Ar⁺) in the plasma, accelerated by an electric field, bombard the substrate surface vertically.

②. Effect: Directly impacting material atoms through momentum transfer, detaching them from the surface.

Chemical reaction

· Principle: Active free radicals (such as F·, Cl·, O·) in the plasma diffuse to the surface and react chemically with the material to produce volatile products.

· Effect:

① Silicon (Si) + 4F → SiF₄↑ (gas)

② Silicon dioxide (SiO₂) + 4HF → SiF₄↑ + 2H₂O↑

③ Photoresist (organic) + O → CO₂↑ + H₂O↑

Ion-enhanced reaction

· Principle:

Ion bombardment breaks chemical bonds in the material, increasing surface activity.

Ion bombardment removes reaction byproducts/passivation layers, exposing fresh surface.

Ion energy controls the directionality of the reaction (vertical bombardment suppresses lateral reactions).

· Result:

Achieves a balance of high selectivity and high anisotropy, resulting in fine patterns with vertical sidewalls.