水印版1.png)

Please submit your message online and we will contact you as soon as possible!

Download

Product Features

SPK-500S wide-width RF plasma cleaning system is a customizable wide-width linear plasma line system that does not damage the surface of materials and does not cause arc breakage, arc deflection, or arc failure. It does not require a vacuum chamber or hazardous gas extraction system.

水印版1.png)

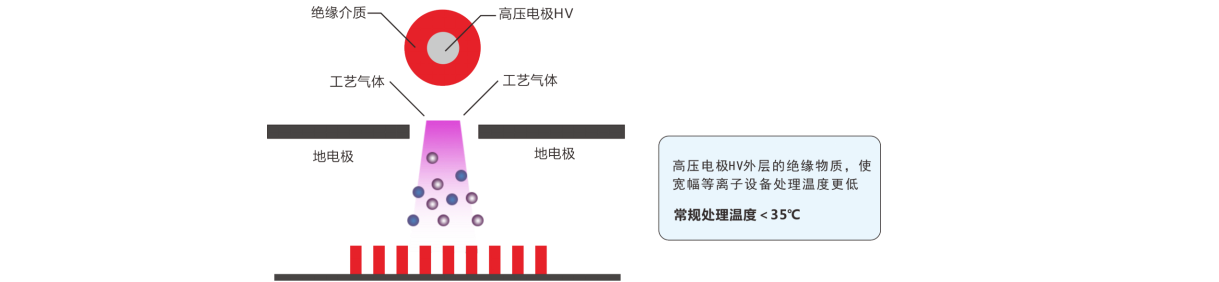

Plasma surface treatment is to ionize the gas into plasma by applying sufficient energy to it. The "active" components of plasma include: ions, electrons, atoms, active genes, etc. Plasma treatment is to use the properties of these active components to treat the surface of the sample, so as to achieve cleaning, modification, etching and other purposes.

The structure of the wide-width plasma cleaning machine is mainly divided into four major components: high-voltage excitation power supply, linear plasma generating device, gas delivery system, and control system.

(A)High voltage excitation power supply:The RF power supply (13.56MHz) is used for excitation to ensure uniform plasma and stable processing. The parameters can be adjusted according to the actual situation of the sample, and the modified effect has been achieved.

(B)Linear plasma generating device:Using a unique plasma generating structure, the conventional processing temperature is less than 35 °C, uniform and stable, and the service life and performance of the equipment are improved and guaranteed.

(C)Gas delivery system:With Ar and O₂ gas, according to the different cleaning materials, with different gases.

(D)Control System:The role of the control system is to control the operation of the entire wide-width radio frequency plasma cleaning equipment, as well as the protection of the overall system.

| Equipment size | 1800*1107*1675mm(L*W*H) |

| weight | 280KG |

| demand power | AC 220V/50Hz single phase 2.5KW |

| power supply | 0-600W adjustable |

| Power frequency | 13.56MHz |

| matcher | Fully automatic vacuum capacitor matcher |

| processing area | 500mm |

| muzzle size | 570*90*74mm(L*W*H) |

| weight | 10KG |

| Adjustable height of the tip | 0-30mm (adjustment accuracy ±0.3) |

| Commonly used processing height | Within 1-5mm |

| Nozzle cooling range | 30-35℃ |

| use gas | Ar and O2 two-way gas |

| Ar gas adjustment range | 20-25L/min |

| O2 gas adjustment range | 0-50SCCM |

| pipeline speed | 0-100mm/s adjustable |

| conveyor belt | 1.8 meters |

| Belt material | Anti-slip PU |

| Induction system | Air pressure alarm, power alarm |

| Call the police | With sound and light alarm function |

Please submit your message online and we will contact you as soon as possible!